Industry

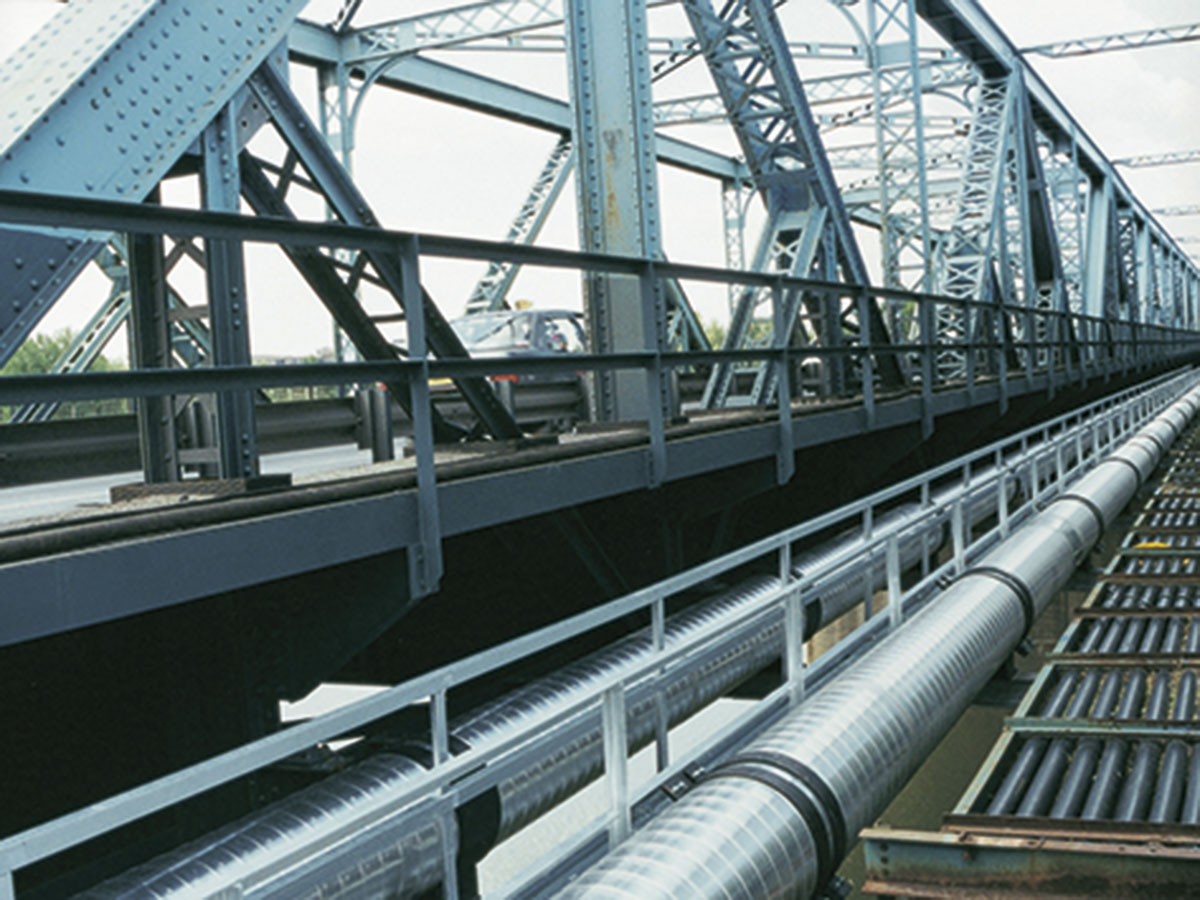

isoplus provides a wide range of products for many different industrial applications and types of industrial media. Our pre-insulated pipes can be used for media such as waste water, oil, water, steam and chemical products.

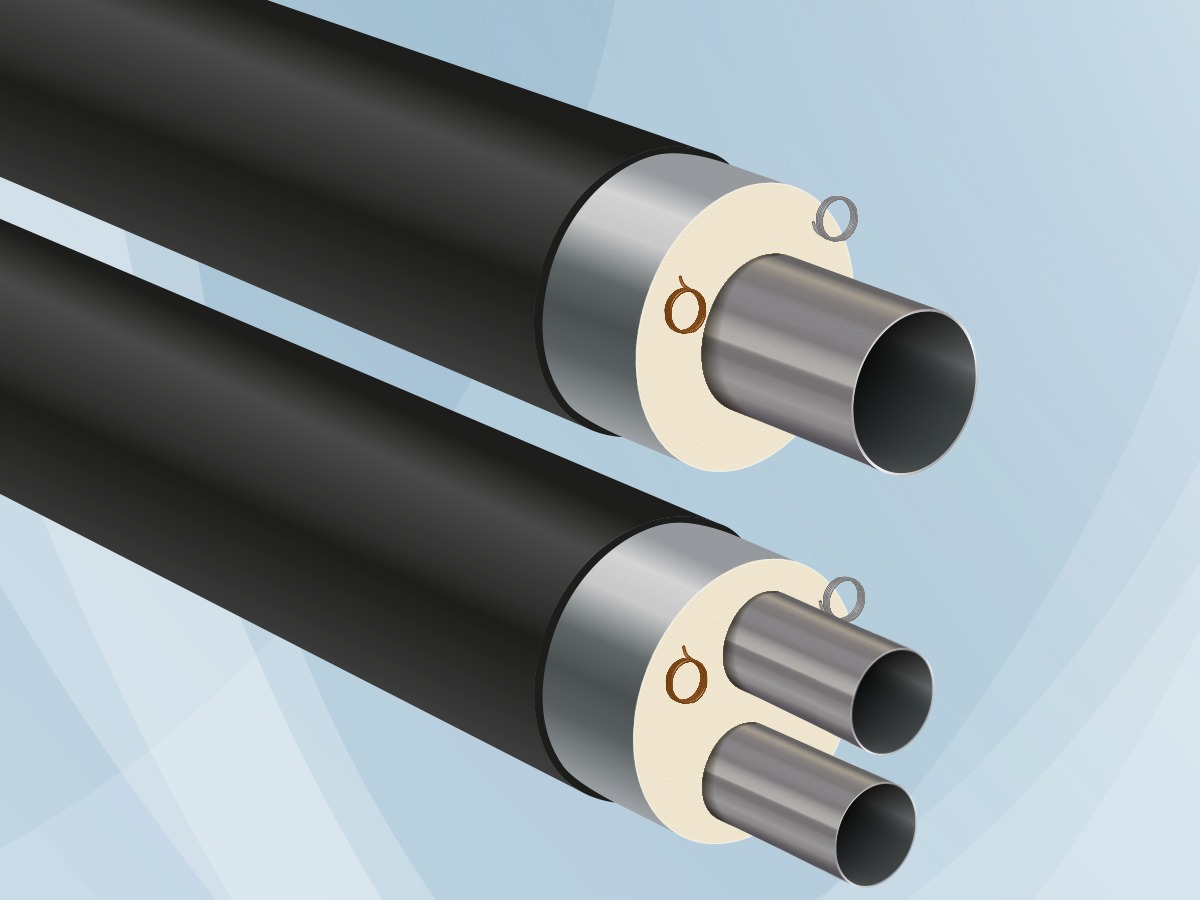

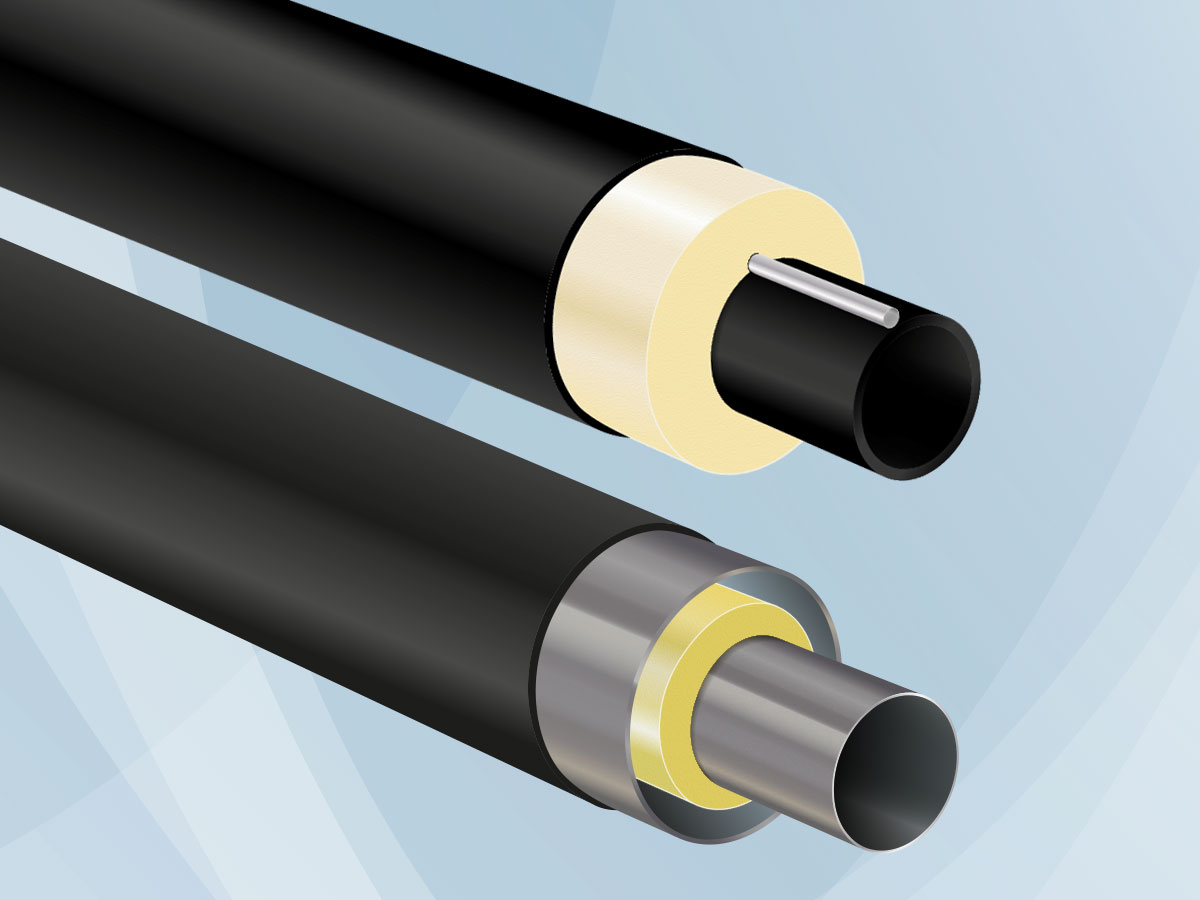

Different steel and plastic pipes are used as carrier pipes in industrial pipe systems. Steel-in-steel pipes are particularly suited for industrial applications and can be produced as pre-insulated pipes with polyurethane insulation.

Polyurethane insulation allows temperatures in the range from -180 to +160C. This secures low heat loss throughout the system’s technical lifetime. Steel-in-steel pipes are available with mineral wool insulation for temperatures up to 400C.

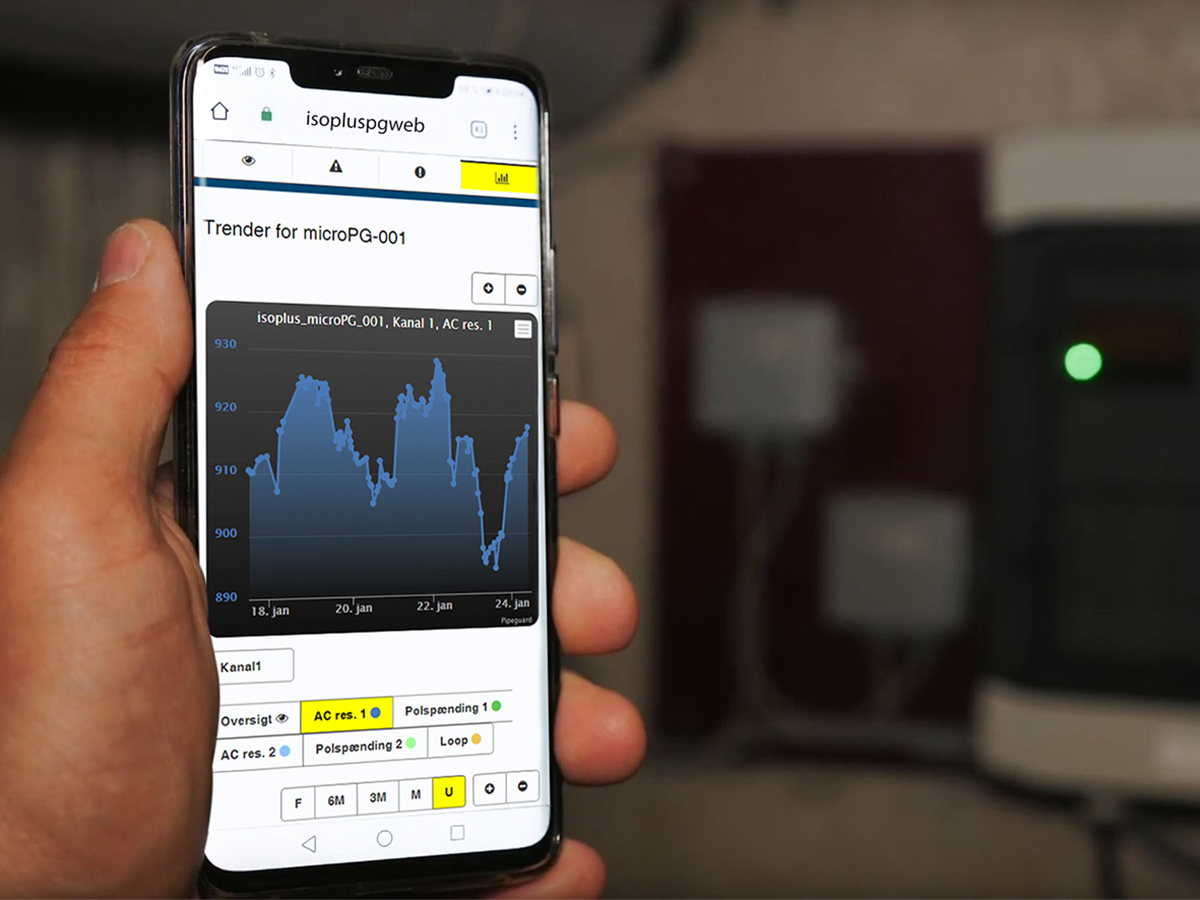

For optimal pipe insulation, industrial solutions can be equipped with a leak detection system. Besides that isoplus offers solutions with tracer pipes for heat tracing or signal cables, to provide the most reliable piping system.

Complete solution for your project

We focus on qualified guidance during the entire process from project start to installation of the piping system.

Our experienced technical team can design and compile a complete pipe system for industrial applications. We tailor pre-insulated pipes, components and fittings to meet the requirements of an individual project. This way, you can be sure to get the best and most efficient solution.

Pipes and fittings for industrial solutions

Steel pipe

Pre-insulated steel pipe is a solid and efficient solution for district heating, cooling as well as industrial applications that require high temperature and pressure resistant pipes.

isoclima

isoclima is a flexible pipe system made of fracture and impact resistant HDPE, particularly suited for the transport of cold water.

Joints and fittings

isoplus offers a complete range of joints, joint assemblies, fittings and other accessories, all tailored to the pipes and easy to install and maintain.

isoplus’ industrial references

| Project | Customer | Media | Main pipe | Jacket pipe | Insulation | Dimensions | Length | Delivery | Sales responsible |

| Danpo A/S | Verdo Energy Systems A/S | Steam and hot oil | Seamless steel pipe P235GH TC1 / EN 10216-2 | Black / white PE | Mineral wool | DN 100 DN 150 | 228 m | April 2018 | Ulrik Kure |

| Alleen, The Old Town, Copenhagen | Brøndum A/S | Utility water | Stainless steel pipes EN1.4404/AISI 316L | Black PE | PUR | ø35, ø42, ø54, ø75 mm | 500 m | July 2018 | Bo Olsen |

| Panum Institute, Copenhagen | HOFOR A/S | Steam | Welded steel pipes P235GH TC 1 / EN 10217-2 | Black PE | Mineral wool | DN 100 DN 150 DN 200 | 300 m | July-December 2017 | Bo Olsen |

| Torveparken, Gladsaxe | John A. Hansen A/S | Utility water/ district heating | Viega sanpress | Black PE | PUR | ø28, ø35, ø42, ø54, ø76, ø88 mm | 2400 m | 2018-2019 | Bo Olsen |

| Sewer expansion Aqissilik and Ukalilik, Greenland | Brøndum Greenland | Waste water | PE100 SDR17 PN10 | Black PE | PUR | ø160 mm | 312 m | August 2018 | Bo Olsen |

| Stock order, Greenland | Brøndum Greenland | Waste water 4 tracer pipes | PE100 SDR17 PN10 | Black PE / Spiro | PUR | ø110 mm ø160 mm | 240 m | August 2018 | Bo Olsen |

| Nordhavnstunnellen, Copenhagen | Wicotec Kirkebjerg | Water for fire estinguising2 tracer pipes | PE100 SDR11 PN16 | Black PE | PUR | ø225 mm ø315 mm | 750 m | January-July 2017 | Bo Olsen |