Production

This ensures major flexibility and security of supply.

isoplus manufactures traditional steel-in-plastic pipe systems as well as flexible pipe systems, which are particularly suited for branch lines and small distribution networks; they can easily bypass any underground obstacles.

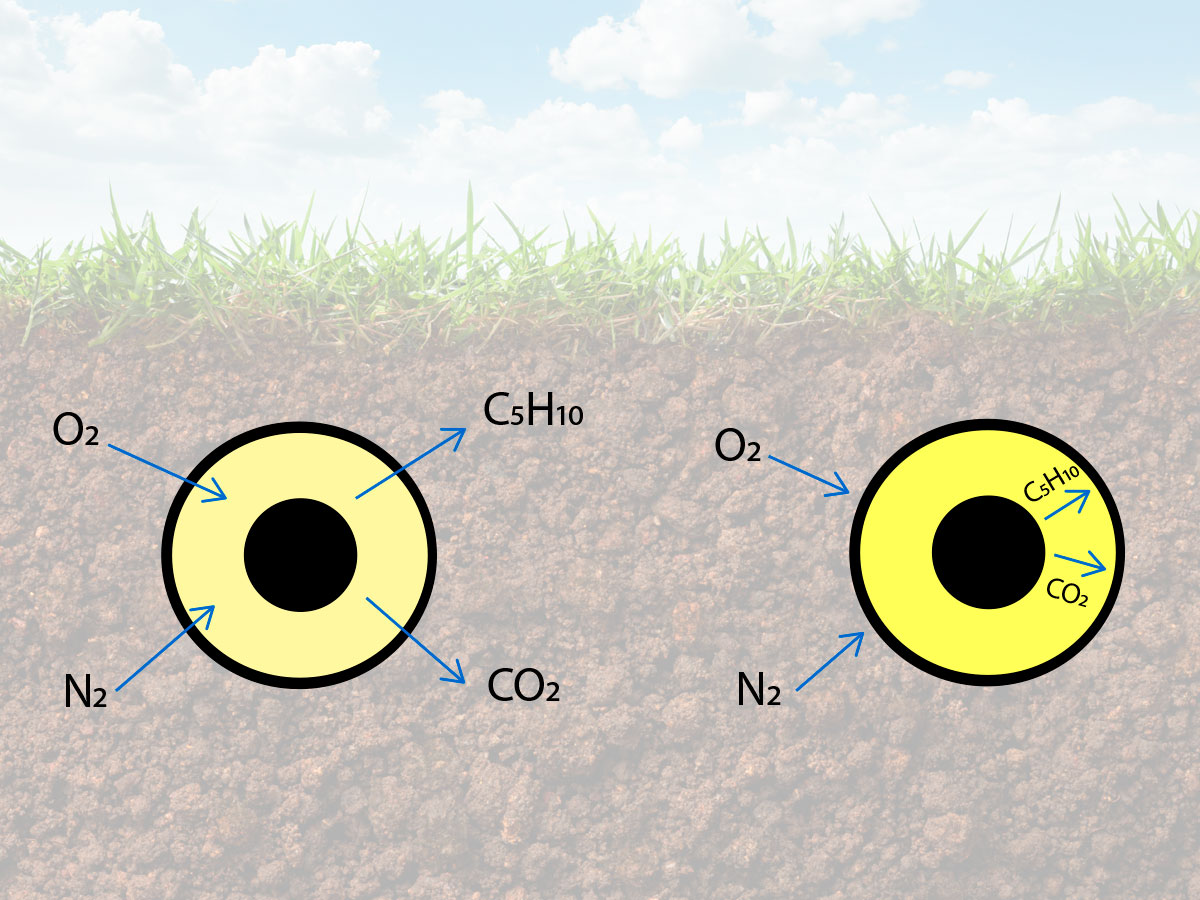

Innovative product development in line with market requirements and based on the newest technology is an important part of our work. In our high-tech continual production lines, we manufacture pre-insulated pipes with gas diffusion barriers between polyurethane foam and jacket pipe. The gas diffusion barrier ensures constant low heat loss throughout the system’s service life.

For all types of systems, we use an efficient polyurethane foam, which is protected by impact and fracture resistant PE jacket. This structure warrants high reliability and a service life of 30-50 years.

Our quality assurance staff takes regular foam samples in order to ensure that the insulation complies with the requirements of DS/EN 13941, and they conduct final inspections to ensure that measurements and dimensions remain within the approved tolerances.

The scope of our quality control is described in detail together with isoplus’ quality assurance and ISO 9001 certification.

Fittings are checked in accordance with DS/EN 13941.

About isoplus

Since the company’s foundation in 1993, we have kept up to date with the development and researched new technologies to provide the best, most efficient and most sustainable solutions for district heating and district cooling.

Organisation

isoplus Denmark is a part of the isoplus group, which includes separate production sites and sales companies all over Europe.

Environment & sustainability

isoplus constantly works to ensure that current environmental requirements are met everywhere in the isoplus group.

Waste management

Manufacturing of pre-insulated pipe systems generates a minor amount of residual waste, which is subject to clear disposal procedures.